Industry 4.0 and How it Revolutionized Asset Monitoring in Manufacturing Sector

Industry 4.0, also known as the Fourth Industrial Revolution or 4IR, brings forth the integration of digital technology and intelligent automation into the physical world of manufacturing. By harnessing the power of the Internet of Things (IoT), Smart Cities, Cloud Computing, and Artificial Intelligence, it enables faster, more efficient, and personalized production of goods while cutting costs.

Industry 4.0 brought a paradigm shift in manufacturing by leveraging cutting-edge technologies and data-driven insights, transforming manufacturing operations. Here, we delve into some of the foremost advantages and benefits –

Real-Time Data Monitoring

Integrating IoT devices and sensors into manufacturing equipment enables valuable data collection in real time. This constant stream of information offers manufacturers an accurate understanding of asset conditions around the clock, facilitating swift responses to emerging faults.

Remote Monitoring and Diagnostics

With cloud computing and interconnected systems, maintenance teams can access real-time asset health data anywhere. This remote capability promotes efficient monitoring and quick diagnostics without physical presence, thus saving valuable time, money, and resources.

Data Analysis and Insights

The digitized nature of Industry 4.0 enables the collection, management, and analysis of vast quantities of data across numerous assets. Leveraging machine learning and artificial intelligence (AI/ ML), users can extract valuable insights from this data trove and make informed decisions.

Predictive Maintenance

Combining real-time data and machine-learning algorithms allows manufacturers to predict when an asset is likely to fail accurately. Driven by this foresight, potential issues can be addressed before they escalate, saving on repair costs, eliminating unplanned downtime, and extending equipment lifespan.

Collaboration

Furthermore, Industry 4.0 promotes seamless collaboration between teams across the supply chain through real-time data sharing, remote access, and centralized control. Manufacturers can achieve an agile and responsive environment by breaking down silos with streamlined coordination and communication.

Real-Time Asset Health Monitoring

A new chapter has unfolded where advanced breakthrough technologies are transforming traditional factories into intelligent, data-driven powerhouses, revolutionizing how manufacturers operate and maintain their valuable equipment resulting in operational efficiency and cost optimization. But before we dig into it, let us understand how traditional monitoring methods in manufacturing are burdened with multiple challenges.

Drawbacks of Traditional Asset Monitoring Methods in Manufacturing

Lack of real-time insights: As manual data collection introduces delays in issue identification, traditional monitoring methods lack real-time insights.

Inefficiency and human error: Manual data collection is susceptible to human errors, inconsistencies, and delays, thus compromising the accuracy of analysis and insights.

Reactive approach: Relying on a reactive approach to issue resolution leads to production disruptions, quality issues, and increased repair costs.

Difficulty in scalability: Traditional monitoring methods struggle to scale alongside production and manufacturing processes, as manual data collection is burdensome and error-prone in complex setups.

Lack of integration and connectivity: The isolated nature of traditional methods inhibits incorporating advanced transformative technologies like machine learning and smart automation.

Limited visibility: Traditional monitoring methods fail to provide end-to-end visibility, restricting traceability and hindering the identification of bottlenecks.

Benefits of Real-Time Asset Health Monitoring

As a game-changer, real-time asset health monitoring provides a myriad of invaluable benefits.

Proactive Maintenance: Real-time asset health monitoring helps identify early signs of deterioration, enabling proactive maintenance scheduling to prevent major breakdowns, minimize downtime, and avoid operational disruptions.

Increased Asset Availability: The equipment monitoring system can swiftly identify malfunctioning assets and alert personnel proactively. This promptness allows for quick troubleshooting and ensures enhanced asset availability.

Improved Reliability and Performance: Organizations can maximize operational efficiency and reliable performance by monitoring critical parameters and maintaining assets healthy.

Cost Optimization: Saves money by detecting and addressing issues promptly and avoiding costly repairs, emergency maintenance, and production losses.

Data-Driven Decision Making: Asset health monitoring systems collect and analyze data on performance, trends, and patterns. This wealth of information helps enterprises to make informed decisions and improve maintenance strategies.

Extended Asset Lifespan: Regular monitoring helps identify and address issues that may lead to premature asset failure. By extending the lifespan of assets, organizations optimize their investment and reduce the need for frequent replacements.

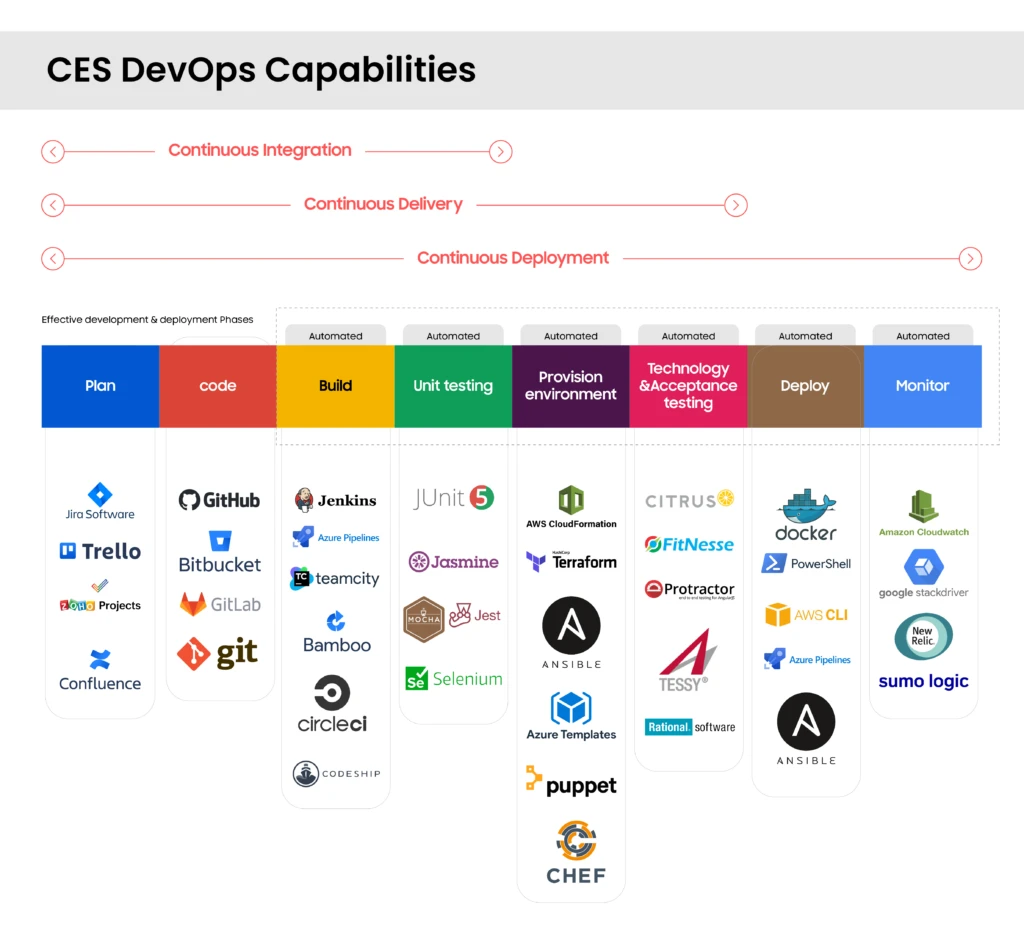

Embrace Digital Transformation with CES as Your Reliable Partner

Embracing Industry 4.0 is not just about adopting new technologies; it’s about unleashing a transformation that redefines how you do business. In this transformative process, CES is committed to providing continuous support and expertise to help enterprises navigate the complexities and seize the opportunities presented by Industry 4.0.

Our experts work closely with your team, providing in-depth insights and hands-on assistance to optimize the integration of Industry 4.0 technologies into your existing processes. Our services help organizations harness the power of data-driven decision-making, predictive maintenance, and interconnected systems, gaining a competitive advantage in the rapidly evolving market. Our comprehensive range of services includes:

- IoT Integration: We seamlessly deploy, manage, and analyze IoT devices, allowing for real-time monitoring, process automation, and optimization.

- Cloud Computing: We help you harness cloud infrastructure’s scalable and flexible capabilities to collect, store, and analyze the vast volumes of data generated with Industry 4.0 technologies.

- Custom Web and Mobile Applications: We build tailored web and mobile applications to provide visualized real-time data collected from IoT devices, sensors, and machines in a user-friendly interface.

- Analytics and Reporting: We collect valuable data from diverse assets and transform it into detailed reports with actionable insights, aiding you in making educated business decisions.

- Artificial Intelligence and Machine Learning: We develop and deploy advanced AI and ML algorithms that automate processes, unlock predictive insights, and reveal data patterns.

Transform your Manufacturing future with Industry 4.0. Reach out to our experts at info@cesltd.com.