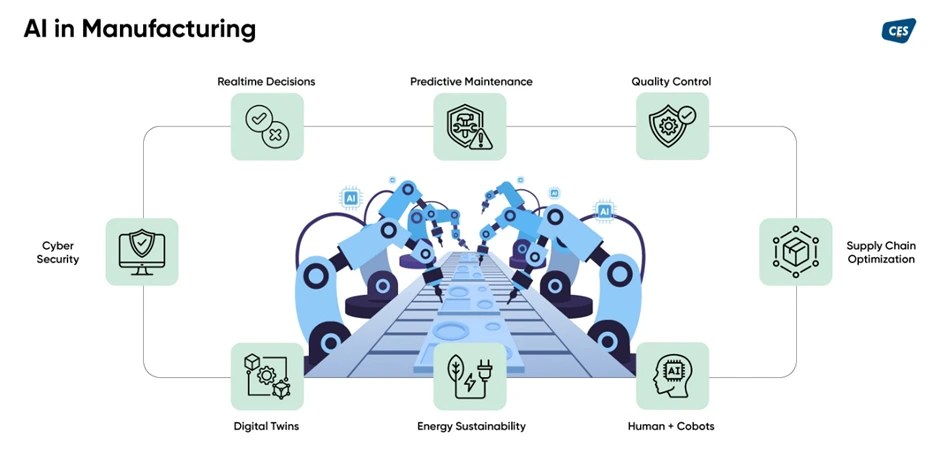

AI in Manufacturing: Powering the Digital Transformation

The manufacturing industry is undergoing a seismic shift, fuelled by the rapid evolution of digital technologies. At the forefront of this transformation is Artificial Intelligence (AI) a catalyst for smarter operations, enhanced productivity, and agile decision-making. From predictive maintenance to intelligent automation, AI is redefining how factories operate in the digital age.

Smarter Decisions with Real-Time Data

AI empowers manufacturers to harness vast amounts of sensor, machine, and system data. Machine learning algorithms analyze these inputs in real time to uncover patterns, detect inefficiencies, and deliver actionable insights. The result? Streamlined workflows, reduced downtime, and improved operational efficiency.

Predictive Maintenance: Preventing Failures Before They Happen

Gone are the days of reactive or scheduled maintenance. With AI-driven predictive maintenance, manufacturers use sensor data and historical performance to forecast equipment failures before they occur. This proactive approach reduces repair costs, minimizes unplanned downtime, and extends machine lifespans.

Revolutionizing Quality Control

AI-powered vision systems outperform human inspectors by detecting defects with unmatched precision. By comparing items against predefined quality benchmarks, these systems reduce waste, ensure compliance, and improve customer satisfaction, all while keeping production lines moving at high speed.

Optimizing the Supply Chain

AI in supply chain management forecasts demand, optimizes inventory, and streamlines logistics. By anticipating disruptions, analyzing market trends, and recommending alternative sourcing strategies, AI ensures resilience and continuity, even in volatile conditions.

Human-Machine Collaboration: The Rise of Cobots

AI doesn’t replace human workers, it enhances them. Collaborative robots (cobots) safely handle repetitive or hazardous tasks, freeing workers for higher-value activities. Meanwhile, AI-driven learning platforms close skill gaps and personalize training, strengthening workforce development.

Driving Sustainability Through Energy Efficiency

Manufacturers face mounting pressure to reduce energy use and emissions. AI-powered energy monitoring identifies inefficiencies across production lines, enabling smarter resource management. The outcome: lower energy consumption, reduced carbon footprint, and progress toward sustainability goals.

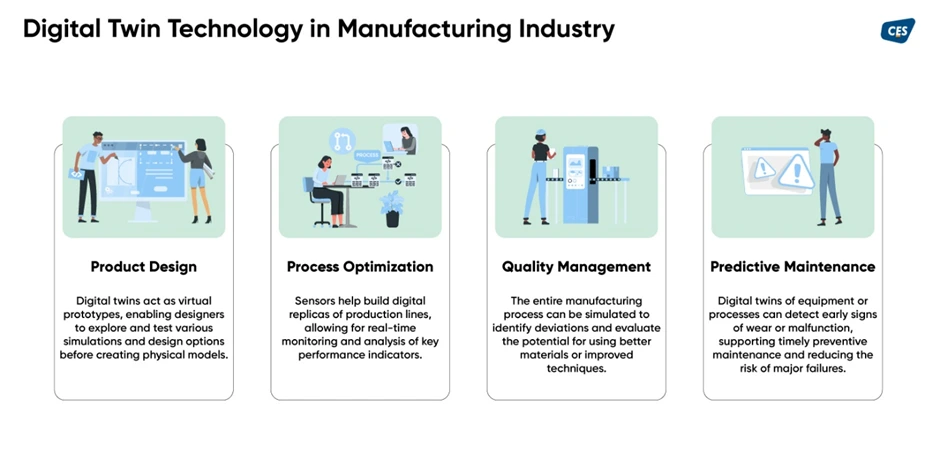

Digital Twins: Simulating the Future

Digital twin technology, virtual replicas of physical systems, allows manufacturers to simulate scenarios, monitor performance, and optimize processes without disruption.

Case Study Spotlight: Digital Twins in Action

As part of CES’s smart manufacturing initiative, Digital Twins were implemented for injection moulding assets such as Silos, Blenders, Dryers, HyPET, and HyCAP. These virtual replicas enabled real-time monitoring, diagnostics, and predictive maintenance.

Plant teams could:

- Visualize machine KPIs

- Track historical trends

- Proactively manage maintenance via alerts and ticketing systems

This approach improved operational efficiency, reduced downtime, and empowered data-driven decision-making across production lines.

Strengthening Cybersecurity

As factories embrace connectivity, cybersecurity in manufacturing becomes critical. AI-powered systems detect anomalies, identify vulnerabilities, and enable automated threat responses, protecting infrastructure, assets, and sensitive data.

Key Highlights of AI in Manufacturing

- Real-time analytics for smarter decisions and efficiency

- Predictive maintenance to reduce downtime and costs

- AI-based visual inspection for superior quality control

- Supply chain forecasting and logistics optimization

- Cobots that enhance, not replace, human workers

- AI-driven energy management for sustainability

- Digital twins for simulation and scenario planning

- AI-enhanced cybersecurity for connected factories

- Tailored AI solutions for industries like automotive, electronics, and pharma

How CES Accelerates Your AI Journey

Every AI adoption journey begins with a vision, modernizing systems, unlocking insights, or improving customer experiences. Yet challenges like integration, scalability, and compliance often slow progress.

At CES, we partner with organizations to bridge this gap through:

- Legacy Transformation: AI-enabled architectures that modernize legacy systems.

- Predictive Analytics: Trend forecasting to optimize operations.

- Conversational AI: Chatbots and assistants that enhance service.

- Computer Vision: Automating inspections and improving inventory management.

- Fraud Detection & Risk Analytics: Identifying anomalies to strengthen compliance.

From replacing outdated systems to unlocking hidden insights, CES has helped manufacturers embrace AI in ways that deliver measurable, lasting change.

Your AI Success Story Starts Here

It began with a question: “Can AI really work for us?”

We listened. We understood. We acted.

Today, those same organizations operate with new levels of efficiency, agility, and intelligence. With CES’s AI accelerators, businesses fast-track adoption, skip lengthy trial-and-error, and see results through tailored demos, use cases, or proof-of-concepts.

For forward-thinking manufacturers, AI isn’t just technology, it’s the future of operations, competition, and growth. Ready to power your digital transformation?

Email marketing@cesltd.com to start your AI journey with CES today.